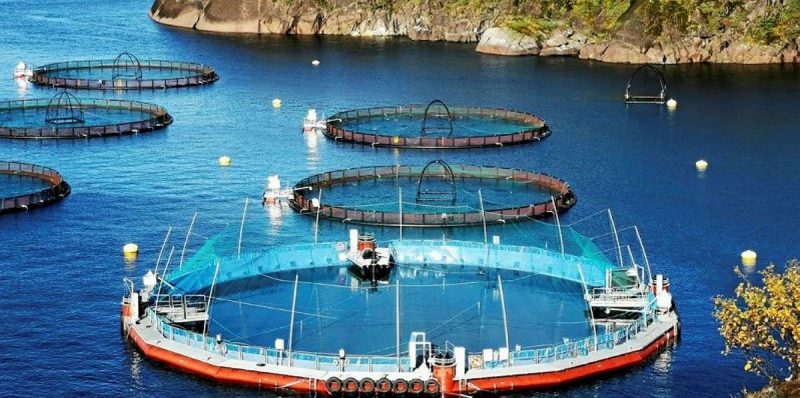

New tech making waves for salmon farmers in B.C.

Cermaq Canada trials new system which will essentially eliminate lateral contact between wild and farmed salmon

By Fabian Dawson

SeaWestNews

New technology is making waves in B.C.’s oceans as salmon farmers continue to make their operations more sustainable to feed the world with affordable protein.

The latest technology to be introduced in B.C. is a new semi-closed containment system (SCCS), which has been trialed by Cermaq in Norway with promising results.

Cermaq Canada says the new SCCS system will essentially eliminate lateral contact between wild and farmed salmon, – the central issue in the polarising debate over ocean-based fish farming in British Columbia.

The company said the system components arrived in Canada earlier this month, and assembly is now underway in Port Alberni on Vancouver Island’s west coast. Once the SCCS structure is complete, it will be taken by barge to Cermaq’s Millar Channel farm site in Clayoquot Sound.

“This is the first step leading up to the planned stocking of the SCCS at our Millar Channel farm site, off the west coast of Vancouver Island in Clayoquot Sound, in the traditional territory of the Ahousaht First Nation, later this fall,” said David Kiemele, Managing Director for Cermaq Canada.

“The system also allows for greater precision in farming by providing increased oversight of the environment inside the system by controlling water temperature, dissolved oxygen and preventing sea lice and algae from entering the system,” he said.

This first of its kind system outside of Norway, uses a patented material to form a fully enclosed lining, or bag, to encompass the SCCS structure.

Naturally occurring algae, some species of which can be harmful to fish, and sea lice are usually found in the top layers of the water column. The new system will allow Cermaq Canada to set the sea water intakes below this depth, which will intentionally limit the introduction of these two organisms into the farm system.

“These sea water intakes are able to be set at site specific depths which provides many benefits. We will investigate setting the intakes at deeper depths, to limit introducing sea lice and algae and to stabilize the environment in the system. This evaluation is a key component as we assess the technology for future use in British Columbia,” said Linda Sams, Sustainable Development Director for Cermaq Canada.

“We are just finishing our second trial producing one kilogram salmon, in a semi-closed cage in Norway, similar to the one being deployed in Canada, and we are very excited by the results,” said Kiemele.

“During both trials, a control system was anchored adjacent to the new SCCS. The fish within the SCCS showed consistently better growth, overall improved performance and almost no occurrence of sea lice within the SCCS. We are looking forward to testing this technology under Canadian conditions, which we know are quite different than those seen in Norway,” added Kiemele.

The system was designed and built by FiiZK in Norway and shipped in components to Canada. After reviewing several proposals, Cermaq Canada selected Canadian Maritime Engineering (CME) to oversee and manage the assembly.

“We will be using local labour, including pipe fitters, safety and security for the duration of the assembly which is expected to take approximately eight to 10 weeks,” said Jim Drummond, Lead Project Manager for CME.

“All assembly will be located within the CME Canal Beach location in downtown Port Alberni and we look forward to working with representatives from FiiZK and Cermaq on this new system.”

Upon completion of this project, Cermaq will develop a roadmap for potential SCCS implementation in parts of its operations, including the description of required technology improvements and potential of suitable sites for this type of system.

Cermaq’s trialing of the new system in BC comes in the wake of a government report last February that concluded new aquaculture technologies, as well as conventional net-pen systems, will all play a role in contributing to global production of salmon

The report said that land-based recirculating aquaculture system (RAS) technology requires the use of large amounts of land, water, and power, and thus has a significant environmental footprint, in particular greenhouse gas emissions.

Other challenges to land based RAS grow-out facilities include the global shortage of a trained workforce, fish health, broodstock development, stocking densities, and financial risks.

Raising land based Atlantic salmon also costs 12 times more than ocean farming, experts said.

In British Columbia, farm-raised salmon is the province’s highest valued seafood product, the province’s top agricultural export, and generates over $1.5-billion towards the B.C. economy, supporting about 7,000 jobs.

“Our fish go into the ocean free from lice and disease, but do come into contact with the naturally occurring parasite once they enter the sea environment,” said John Paul Fraser, the executive director of the BC Salmon Farmers Association.

“Using a full tool belt of methods, BC’s salmon farmers have made it a priority to monitor, and treat our farmed populations for sea lice in order to help reduce the likelihood of the sea lice spreading back to the wild populations,” he said.

“Through ongoing research & development and investment in new equipment and technologies to take on issues including sea lice, BC salmon farming has emerged as one of Canada’s most sustainable food production sectors.”

Sea lice are naturally occurring parasites found on many species of marine fish. They pose no risk to humans, but may harm tiny juvenile salmon. Salmon farmers have several ways to reduce or eliminate sea lice on their fish so they are not an additional source of infection during the springtime outmigration of juvenile wild salmon.

Canada’s Department of Fisheries and Oceans told SeaWestNews this week :“Sea lice in British Columbia during the 2020 outmigration (March 1 to June 30) have been controlled, with no facilities violating licence conditions. ”

Last year, Mowi Canada West introduced its Aqua Tromoy well-boat, costing about $35 million, which is being used to provide environmentally friendly fish health treatments, and for moving fish from site to site. Mowi Canada West is also looking to see if its ocean-based closed containment and semi-closed farm design, called the “Egg” could be deployed in British Colombia.

Earlier this year, Grieg Seafood B.C., took delivery of the Ronja Islander – a $40-million specially designed vessel – to combat sea lice and act as a ‘fish taxi’ to provide safe handling during live transfers to ocean farms.

(Image shows Cermaq’s Semi-Closed Containment System (SCCS) being trialed in northern Norway)